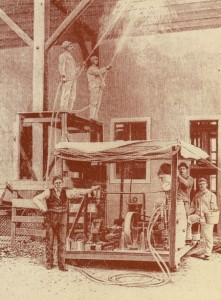

When thinking of painting, one automatically thinks of ready-mixed paint in cans. However, the advent of the paint can is a fairly recent phenomenon. For centuries and going back into antiquity, painters were “ingredient mixers”, as well as applicators. There was no such a thing as ready-mixed paints. Painters mixed their paints as they went along. Whoever knew the formulas had a high level of “job security” in those days!

It was not until 1867 that the first US patent was issued for a read-mixed paint. The ingredients listed in the patent were as follows: oxide of zinc, acetate of lead, sulfate of zinc, silicate of soda diluted in water, lime water and linseed. This list of ingredients may help to explain why, for the better part of the following twenty years, ready-mixed paints had a serious image problem. They were considered to be inferior and undependable.

Then, what is it that caused the balance to tilt in favor of the ready-mixed paints? A few key factors contributed to that outcome. First, the American Industrial Revolution took root during the 1870’s and 1880’s. During that same period, there was also tremendous population growth, fueled by a considerable influx of immigrants. As an example, Chicago’s population grew from 298,000 in 1870 to 1.7 million in 1900. These two forces collided to create the perfect storm for something else to emerge as the painting industry’s driving force: the chemist and paint lab. As the industrial revolution progressed, the needs for painting surfaces became more and more complex and the demand for paints began to outstrip painter’s ability to mix the ingredients. The paint can was born to stay.

As a house painting contractor from the Chicago area, I have always been fascinated by paint memorabilia and the history of the painting industry. I not only have a considerable memorabilia collection, but I also give lectures to interior designers, architects and other interested groups on the History of Paint in America.

Follow

Follow